Welcome to IndustREEL. My name is Luke Sutton.

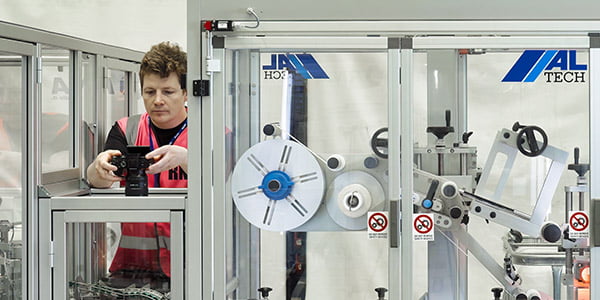

I’m a video producer based in Gloucestershire, specialising in manufacturing, industrial, and corporate video productions. With eight years of hands-on experience, the best equipment in the industry and a drone license, I handle everything from planning to executing video productions for promotional and sales purposes.

Over the years, I’ve collaborated with both small and large international companies, helping them share their message effectively. Working closely with clients and their marketing teams, I’ve had the privilege of filming some incredible projects. My focus is on exceeding expectations and delivering results that make an impact.

Thanks to this experience, I’ve mastered the art of saving you time. I seamlessly integrate with your engineers and staff, ensuring a smooth process to create something extraordinary. What sets me apart is my commitment to being reliable, punctual, and perceptive in the industrial landscape.

VIDEO PRODUCTION

I had the incredible opportunity to film at Proroll Ltd, a leading metal manufacturer in Sheffield. Here’s a glimpse into their melting process.

Our upcoming production will feature a comprehensive trade show video showcasing Proroll’s metal melting techniques and manufacturing prowess. Additionally, we’ll include individual interview segments with subtitles, adding depth to the presentation for an upcoming trade show event.

What kind of price are we looking at?

I’m looking at anywhere from £1650 to north of £2000 for a 3-minute video production with two revisions. For long distances accommodation and mileage is factored into pricing.

I’m interested in video production. What are the next steps?

Send me an email using the contact form here and we’ll schedule a video call. Once we have discussed your needs and objectives, we can decide and plan the specific shoot day and then get to work.

We aren’t exactly sure what we need. Can you advise us?

Absolutely. I’ve worked with hundreds of different clients and always stay updated on the current best trends in the industry. We can happily discuss your requirements in a free video call.

Do you only film machines, or can you film interviews, etc.?

I can film anything. Whether you need a talking head video, an interview, an event video production, or a training video, I can handle it. I’m not limited to just industrial or manufacturing video production.

Do you do photography?

I am a professional photographer and videographer so professional headshots as well as industrial photography is an optional service. Take a look at my photography here.

Can you film aerial shots?

I have both the A2 Certificate of Competency and General Visual Line of Sight Certificate, and many hours of flight under my belt. A copy of my licence can be seen upon request.

What is the process of getting a video production done?

Once we decide on a shoot date, I’ll email you the plan we agreed to along with a deposit invoice.

On the shoot day, I’ll film aerial shots and interviews in the morning (if required) and then office shots and machinery shots in the afternoon.

With all the footage, I will then create a production for your review which will need your input for small changes etc. Once you are happy with the final video, I will send it to you digitally and invoice you.

What do we need to do before the shoot?

It would be a good idea to tidy the factory and manufacturing areas. Remove any items like fizzy drink bottles from office areas, dust from the tops of machines, wipe down panels, and sweep the floors free from manufacturing debris. It’s also advisable to check if your staff is comfortable being filmed. If not, I can work around them on the day.

Do we need to do anything on the day of the shoot?

Ideally, if you can assign somebody to assist me for the day, perhaps a member of your marketing team or a supervisor onsite. I’ll need help with engineers and floor staff to get the right shots we need.